为电网注入绿色能源

虽然能效和行业标准是光伏逆变器技术发展的主要推动力,但可靠性也是一个重要的因素。

现代环保建筑的最新趋势是蓝色 ── 更正确来说应该是深蓝色的太阳能板。即使是经济危机和各国政府降低可再生能源的收购价格,也无阻这个发展势头。

现在,这些太阳能发电系统的拥有者已不在乎太阳能板会不会影响建筑外观,而是关注如何提高系统的发电量和可靠性。(不要忘记,在1990年代,所谓“能效”是指在整个系统寿命期间产生超过7000功率温度周期(power temperature cycle)而已!)

《为电网注入绿色能源》一文 (英文版) 将讨论良好可靠的电源开关如何为绿色电源建立关键的基础。

Photovoltaic systems can be found almost anywhere now. It all started in Germany, today the biggest market for PV systems and home of the biggest cell and inverter manufacturers, and at the same time enjoying a solar irradiation level similar to Alaska. These systems have seen tremendous technological development over the last years, both in panel efficiency as well as inverter technology. While the panel efficiency is driven largely by fundamental research in how to make a photo diode more efficient, the PV inverter is a fine example of power electronics at its best.

The main factors driving development in PV inverters really are efficiency, reliability, and compliance with existing and upcoming regulations, as well as improving the cost. At the same time, new developments in cell technology beyond monocrystalline silicon are forcing changes in the specifications too.

It is easy to see why efficiency matters the more kilowatt-hours the system puts out, the better. Let’s take an example of two 5-kWp systems, with the inverters having 95% and 96% efficiency. With an average working time of 1,200 h/year and an estimated yield of 80%, the input will be equivalent to 4,800 kWh, and at 1% improved efficiency the better system will produce around 50 kWh more, per year. At current feed-in tariffs this amounts to $34/year, or almost $700 over the expected lifetime of the system!

Reliability is also very important, since maintenance cost for remote systems can be quite expensive. This isn’t simply about the repair cost, since when the inverter is not working, no energy is being fed into the grid, so the yield loss also must be considered.

Today, four different panel types dominate the market:

The efficiency values are industry-average estimates for mass production, and as such can only give a relative indication. Today, around 85% of all panels are built with c-Si (see Fig. 1). But the other cell types are quickly catching on, driven by the fact that less raw materials are needed for making them.

Fig. 1. Monocrystalline silicon cell.

There is a drawback however – the new panel types have a higher ratio of no-load voltage to the voltage at maximum output power, and this implies that the inverter input section must be capable of supporting these higher voltages while at the same time showing good conversion efficiency at lower operating points.

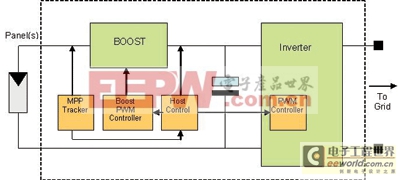

The inverter is the main element between the panels and the grid. It provides proper loading to the cells, to draw the maximum power, and converts this energy into an ac output current.

Fig. 2. The maximum power point tracker helps the inverter draw the maximum power for the inverter to convert to ac output current.

To do this, a maximum power point (MPP) tracker (see Fig. 2) is used. The cells can be thought of as a voltage source with a non-linear source impedance, and the MPP tracker varies the loading until the product of voltage and current is maximized, by changing the input impedance of the boost converter.

In a second stage, this dc current is then converted into the

- 四种思路 四大光伏逆变器并网方式(12-09)

- 光伏逆变器转换效率两大决定因素(12-09)

- 两大主要因素决定光伏逆变器的转换效率(12-08)

- 光伏逆变器特有c知多少?(12-07)

- 光伏逆变器MPPT效率的计算方法与来源(12-07)

- 抑制漏电流:新型单相双Buck光伏逆变器方案(12-31)