四、重新设计之二

时间:10-02

整理:3721RD

点击:

在经过mbed的各种尝试之后,由于无法实现i2cmaster模式——也许这不是主要问题,但是读取RGBW传感器的数据始终不对,因此退而求标准开发模式。简化传输量,将lcm.h的改动部分放上来,没有改动的部分参照实验三。lcm.h改动的代码:

#include "chip.h"

#include "board.h"

#define SDA_SET Chip_GPIO_SetPinOutHigh(LPC_GPIO_PORT, 0, 24 )

#define SDA_CLR Chip_GPIO_SetPinOutLow(LPC_GPIO_PORT, 0, 24 )

#define SDA_DIR Chip_GPIO_SetPinDIROutput(LPC_GPIO_PORT, 0, 24)

#define SCK_SET Chip_GPIO_SetPinOutHigh(LPC_GPIO_PORT, 0 ,25 )

#define SCK_CLR Chip_GPIO_SetPinOutLow(LPC_GPIO_PORT, 0, 25 )

#define SCK_DIR Chip_GPIO_SetPinDIROutput(LPC_GPIO_PORT, 0, 25)

#define A0_SET Chip_GPIO_SetPinOutHigh(LPC_GPIO_PORT, 0, 26 )

#define A0_CLR Chip_GPIO_SetPinOutLow(LPC_GPIO_PORT, 0, 26 )

#define A0_DIR Chip_GPIO_SetPinDIROutput(LPC_GPIO_PORT, 0, 26);

#define RST_SET Chip_GPIO_SetPinOutHigh(LPC_GPIO_PORT, 0, 13 )

#define RST_CLR Chip_GPIO_SetPinOutLow(LPC_GPIO_PORT, 0 , 13 )

#define RST_DIR Chip_GPIO_SetPinDIROutput(LPC_GPIO_PORT, 0, 13)

#define CS_SET Chip_GPIO_SetPinOutHigh(LPC_GPIO_PORT, 0, 17 )

#define CS_CLR Chip_GPIO_SetPinOutLow(LPC_GPIO_PORT, 0, 17 )

#define CS_DIR Chip_GPIO_SetPinDIROutput(LPC_GPIO_PORT, 0, 17)

#define LED_SET Chip_GPIO_SetPinOutHigh(LPC_GPIO_PORT, 0, 16 )

#define LED_CLR Chip_GPIO_SetPinOutLow(LPC_GPIO_PORT, 0, 16 )

#define LED_DIR Chip_GPIO_SetPinDIROutput(LPC_GPIO_PORT, 0, 16)

... ...

//Delayer

void delay0(int counter){

int i;

for(i=0;i<counter;i++){;}

}

void setLcdGPIO(void){

SDA_DIR;

SCK_DIR;

A0_DIR;

RST_DIR;

CS_DIR;

LED_DIR;

}

//Write Plus

void wri(void){SCK_CLR;SCK_SET;}

//a B Data to LCD,dt:data,com:1-data/0-command

void b2l(unsigned char dt,unsigned char com){

unsigned char i;

CS_CLR;

if(com) A0_SET;else A0_CLR;

for(i=0;i<8;i++){

if(dt&0x80){SDA_SET;}else{SDA_CLR;};

dt=dt<<1;

wri();

}

CS_SET;

}

...

//END Files//

主函数main.cpp基本按照下载的源代码,只是在主函数中将测试4个数据用循环语句完成,代码短了一些,如下:

#include "board.h"

#include "lcm.h"

static I2CM_XFER_T i2cmXferRec;

#define I2C_CLK_divIDER (40)// System clock is set to 24MHz, I2C clock is set to 600kHz

#define I2C_BITRATE (100000)//100KHz I2C bit-rate

#define I2C_ADDR_7BIT (0x10)//7-bit I2C addresses of I/O expander Note: The ROM code requires the address to be between bits [6:0]||bit 7 is ignored

#define TICKRATE_HZ (100)//SysTick rate in Hz

#define TASK_LOOP while (true)

#define EVENT_LED_BUMP 0x01

#define EVENT_LED_TOGGLE 0x02

static volatile int intErrCode;

static volatile uint32_t ticks;

static uint8_t txData[16];

static uint8_t rxData[16];

static uint32_t event_flag,js;

static uint16_t rgb[4];

void Init_I2C_PinMux(void){

#if (defined(BOARD_NXP_LPCXPRESSO_812) || defined(BOARD_LPC812MAX) || defined(BOARD_NXP_LPCXPRESSO_824))

Chip_Clock_EnablePeriphClock(SYSCTL_CLOCK_SWM);

#if defined(BOARD_NXP_LPCXPRESSO_824)

Chip_SWM_EnableFixedPin(SWM_FIXED_I2C0_SDA);

Chip_SWM_EnableFixedPin(SWM_FIXED_I2C0_SCL);

#else

Chip_SWM_MovablePinAssign(SWM_I2C_SDA_IO, 10);

Chip_SWM_MovablePinAssign(SWM_I2C_SCL_IO, 11);

#endif

Chip_IOCON_PinSetI2CMode(LPC_IOCON, IOCON_PIO10, PIN_I2CMODE_FASTPLUS);

Chip_IOCON_PinSetI2CMode(LPC_IOCON, IOCON_PIO11, PIN_I2CMODE_FASTPLUS);

Chip_Clock_DisablePeriphClock(SYSCTL_CLOCK_SWM);

#else

#warning "No I2C pin muxing defined"

#endif

}

void dispBase(void);

void dispMes(void);

void delay(uint16_t counter){

int i,j;

for(i=0;i<counter;i++)

for(j=0;j<i;j++){;}

}

void setupI2CMaster(){

Chip_I2C_Init(LPC_I2C);//Define P0_11,P0_10 for I2C

Chip_I2C_SetClockDiv(LPC_I2C, I2C_CLK_divIDER);

Chip_I2CM_SetBusSpeed(LPC_I2C, I2C_BITRATE);

Chip_I2CM_Enable(LPC_I2C);

}

void SetupXferRecAndExecute(uint8_t devAddr,uint8_t *txBuffPtr,uint16_t txSize,uint8_t *rxBuffPtr,uint16_t rxSize){

i2cmXferRec.slaveAddr = devAddr;

i2cmXferRec.status = 0;

i2cmXferRec.txSz = txSize;//=2

i2cmXferRec.rxSz = rxSize;//=0

i2cmXferRec.txBuff = txBuffPtr;

i2cmXferRec.rxBuff = rxBuffPtr;

Chip_I2CM_XferBlocking(LPC_I2C, &i2cmXferRec);

}

void sendI2CMaster(uint16_t i2c_addr, uint32_t ledStateOut){

int index = 0;

txData[index++] = (uint8_t) 0x16; /* I2C device regAddr */

txData[index++] = (uint8_t) ((ledStateOut) & 0xff); /* I2C device regVal */

txData[index++] = (uint8_t) ((ledStateOut >> 8) & 0xff);/* I2C device regVal */

txData[index++] = (uint8_t) ((ledStateOut >> 16) & 0xff);/* I2C device regVal */

txData[index++] = (uint8_t) ((ledStateOut >> 24) & 0xff);/* I2C device regVal */

SetupXferRecAndExecute(i2c_addr, txData, 5, rxData, 0);

}

void SysTick_Handler(){

ticks++;

if ((ticks % 50) == 0){event_flag |= EVENT_LED_BUMP;}

if ((ticks % 125) == 0){event_flag |= EVENT_LED_TOGGLE;}

}

int main(){

uint16_t txSize,rxSize,last_Data;

uint8_t i,j,times=16;//LSB,MSB,;

uint32_t sum_data;

SystemCoreClockUpdate();

Board_Init();

Init_I2C_PinMux();

setupI2CMaster();

NVIC_DisableIRQ(I2C_IRQn);

setLcdGPIO();

lcdInit();

lcdClear();

dispBase();

txSize = 2;

rxSize = 0;

txData[0]=0x00;

txData[1]=0x10;// (0x10) [16] 2 [16] 0

SetupXferRecAndExecute(I2C_ADDR_7BIT, txData,txSize, rxData, rxSize);

delay(times);

last_Data=0;

txSize = 1;

rxSize = 2;

while(1){

//Test RGBW a Roller

for(j=0;j<4;j++){

txData[0]=0x08+j;

sum_data=0;

for(i=0;i<times;i++){ //0x10 0x08 1 [16] 2

SetupXferRecAndExecute(I2C_ADDR_7BIT, txData,txSize, rxData, rxSize);

delay(100);

last_Data=((rxData[1]<<8)+rxData[0]);

sum_data+=last_Data;

}

rgb[j]=sum_data/times;

}

js++;

dispMes();

LED_CLR;

delay(times*5);

LED_SET;

}

}

//Display Base

void dispBase(void){

c2l(0,0,42);c2l(0,1,51);//JS

c2l(1,0,33);c2l(1,1,16);c2l(1,8,33);c2l(1,9,17);//A0,A1

c2l(2,0,48);c2l(2,1,55);c2l(2,2,17);c2l(2,8,48);c2l(2,9,55);c2l(2,10,18);//PW0PW1

c2l(3,0,50);c2l(3,1,26);c2l(3,8,39);c2l(3,9,26);//R:G:

c2l(4,0,34);c2l(4,1,26);c2l(4,8,55);c2l(4,9,26);//b:W:

c2l(5,0,48);c2l(5,1,42);c2l(5,2,18);c2l(5,3,24);//PJ28

}

//Display Test

void dispMes(void){

c2l(0,3,16+(js/100000)%10);c2l(0,4,16+(js/10000)%10);c2l(0,5,16+(js/1000)%10);c2l(0,6,16+(js/100)%10);c2l(0,7,16+(js/10)%10);c2l(0,8,16+(js)%10);

c2l(3,3,16+(rgb[0]/1000)%10);c2l(3,4,16+(rgb[0]/100)%10);c2l(3,5,16+(rgb[0]/10)%10);c2l(3,6,16+(rgb[0])%10);

c2l(3,11,16+(rgb[1]/1000)%10);c2l(3,12,16+(rgb[1]/100)%10);c2l(3,13,16+(rgb[1]/10)%10);c2l(3,14,16+(rgb[1])%10);

c2l(4,3,16+(rgb[2]/1000)%10);c2l(4,4,16+(rgb[2]/100)%10);c2l(4,5,16+(rgb[2]/10)%10);c2l(4,6,16+(rgb[2])%10);

c2l(4,10,16+(rgb[3]/10000)%10);c2l(4,11,16+(rgb[3]/1000)%10);c2l(4,12,16+(rgb[3]/100)%10);c2l(4,13,16+(rgb[3]/10)%10);c2l(4,14,16+(rgb[3])%10);

}

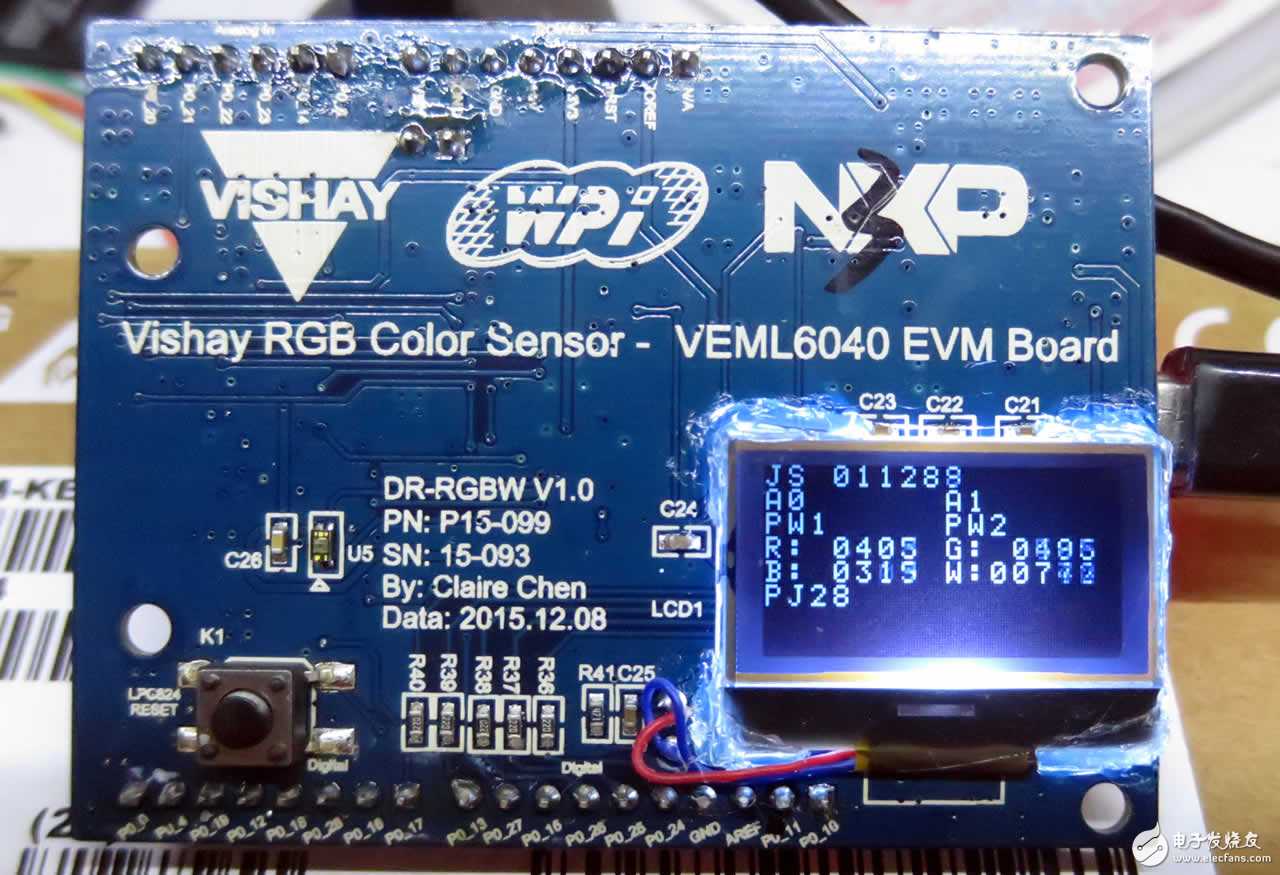

改完的程序仅仅完成驱显,1个程序计数器和1只LED闪烁,ADC、PWM、脉冲产生、检测脉冲需要单独在编写。改回标准编码方法,函数的描述非常长,为了准确的描述一个函数,通常需要从某个变量开始搜索整个项目,而后找到对应函数;很多情况是函数套函数,搜到2~3级之后才能找到正确的变量描述和函数的使用。并且,从PIO的定义就可以看出:使用1个GPIO,需要定义口的输出、输出反向、开时钟、定义高或低,等等多个语句才能完成这个口,比起mbed来确是复杂了许多。这绝对不是编写代码的进步,也绝对不是编程人员的福音——倒是加速成为码农——当然,有些工具可以自动生成代码,但长度绝对可以成为想象中的码农采用机械来耕犁那一望无际的码。结果见照片31,32。程序改完后的运行可靠连续半天没有任何情况发生。需要说明的是循环语句中检测RGBW的循环无法摘出成为一个功能函数,结果是检测十分不稳定,少则几个,多则几分钟的采样数据屏幕就不动了。不知道是什么原因。成为独立函数模块后有些变量成为全局变量,有些事私有变量。这点可以大家一起分析找出原因。因为模块化是C的最爱。谢谢。

#include "chip.h"

#include "board.h"

#define SDA_SET Chip_GPIO_SetPinOutHigh(LPC_GPIO_PORT, 0, 24 )

#define SDA_CLR Chip_GPIO_SetPinOutLow(LPC_GPIO_PORT, 0, 24 )

#define SDA_DIR Chip_GPIO_SetPinDIROutput(LPC_GPIO_PORT, 0, 24)

#define SCK_SET Chip_GPIO_SetPinOutHigh(LPC_GPIO_PORT, 0 ,25 )

#define SCK_CLR Chip_GPIO_SetPinOutLow(LPC_GPIO_PORT, 0, 25 )

#define SCK_DIR Chip_GPIO_SetPinDIROutput(LPC_GPIO_PORT, 0, 25)

#define A0_SET Chip_GPIO_SetPinOutHigh(LPC_GPIO_PORT, 0, 26 )

#define A0_CLR Chip_GPIO_SetPinOutLow(LPC_GPIO_PORT, 0, 26 )

#define A0_DIR Chip_GPIO_SetPinDIROutput(LPC_GPIO_PORT, 0, 26);

#define RST_SET Chip_GPIO_SetPinOutHigh(LPC_GPIO_PORT, 0, 13 )

#define RST_CLR Chip_GPIO_SetPinOutLow(LPC_GPIO_PORT, 0 , 13 )

#define RST_DIR Chip_GPIO_SetPinDIROutput(LPC_GPIO_PORT, 0, 13)

#define CS_SET Chip_GPIO_SetPinOutHigh(LPC_GPIO_PORT, 0, 17 )

#define CS_CLR Chip_GPIO_SetPinOutLow(LPC_GPIO_PORT, 0, 17 )

#define CS_DIR Chip_GPIO_SetPinDIROutput(LPC_GPIO_PORT, 0, 17)

#define LED_SET Chip_GPIO_SetPinOutHigh(LPC_GPIO_PORT, 0, 16 )

#define LED_CLR Chip_GPIO_SetPinOutLow(LPC_GPIO_PORT, 0, 16 )

#define LED_DIR Chip_GPIO_SetPinDIROutput(LPC_GPIO_PORT, 0, 16)

... ...

//Delayer

void delay0(int counter){

int i;

for(i=0;i<counter;i++){;}

}

void setLcdGPIO(void){

SDA_DIR;

SCK_DIR;

A0_DIR;

RST_DIR;

CS_DIR;

LED_DIR;

}

//Write Plus

void wri(void){SCK_CLR;SCK_SET;}

//a B Data to LCD,dt:data,com:1-data/0-command

void b2l(unsigned char dt,unsigned char com){

unsigned char i;

CS_CLR;

if(com) A0_SET;else A0_CLR;

for(i=0;i<8;i++){

if(dt&0x80){SDA_SET;}else{SDA_CLR;};

dt=dt<<1;

wri();

}

CS_SET;

}

...

//END Files//

主函数main.cpp基本按照下载的源代码,只是在主函数中将测试4个数据用循环语句完成,代码短了一些,如下:

#include "board.h"

#include "lcm.h"

static I2CM_XFER_T i2cmXferRec;

#define I2C_CLK_divIDER (40)// System clock is set to 24MHz, I2C clock is set to 600kHz

#define I2C_BITRATE (100000)//100KHz I2C bit-rate

#define I2C_ADDR_7BIT (0x10)//7-bit I2C addresses of I/O expander Note: The ROM code requires the address to be between bits [6:0]||bit 7 is ignored

#define TICKRATE_HZ (100)//SysTick rate in Hz

#define TASK_LOOP while (true)

#define EVENT_LED_BUMP 0x01

#define EVENT_LED_TOGGLE 0x02

static volatile int intErrCode;

static volatile uint32_t ticks;

static uint8_t txData[16];

static uint8_t rxData[16];

static uint32_t event_flag,js;

static uint16_t rgb[4];

void Init_I2C_PinMux(void){

#if (defined(BOARD_NXP_LPCXPRESSO_812) || defined(BOARD_LPC812MAX) || defined(BOARD_NXP_LPCXPRESSO_824))

Chip_Clock_EnablePeriphClock(SYSCTL_CLOCK_SWM);

#if defined(BOARD_NXP_LPCXPRESSO_824)

Chip_SWM_EnableFixedPin(SWM_FIXED_I2C0_SDA);

Chip_SWM_EnableFixedPin(SWM_FIXED_I2C0_SCL);

#else

Chip_SWM_MovablePinAssign(SWM_I2C_SDA_IO, 10);

Chip_SWM_MovablePinAssign(SWM_I2C_SCL_IO, 11);

#endif

Chip_IOCON_PinSetI2CMode(LPC_IOCON, IOCON_PIO10, PIN_I2CMODE_FASTPLUS);

Chip_IOCON_PinSetI2CMode(LPC_IOCON, IOCON_PIO11, PIN_I2CMODE_FASTPLUS);

Chip_Clock_DisablePeriphClock(SYSCTL_CLOCK_SWM);

#else

#warning "No I2C pin muxing defined"

#endif

}

void dispBase(void);

void dispMes(void);

void delay(uint16_t counter){

int i,j;

for(i=0;i<counter;i++)

for(j=0;j<i;j++){;}

}

void setupI2CMaster(){

Chip_I2C_Init(LPC_I2C);//Define P0_11,P0_10 for I2C

Chip_I2C_SetClockDiv(LPC_I2C, I2C_CLK_divIDER);

Chip_I2CM_SetBusSpeed(LPC_I2C, I2C_BITRATE);

Chip_I2CM_Enable(LPC_I2C);

}

void SetupXferRecAndExecute(uint8_t devAddr,uint8_t *txBuffPtr,uint16_t txSize,uint8_t *rxBuffPtr,uint16_t rxSize){

i2cmXferRec.slaveAddr = devAddr;

i2cmXferRec.status = 0;

i2cmXferRec.txSz = txSize;//=2

i2cmXferRec.rxSz = rxSize;//=0

i2cmXferRec.txBuff = txBuffPtr;

i2cmXferRec.rxBuff = rxBuffPtr;

Chip_I2CM_XferBlocking(LPC_I2C, &i2cmXferRec);

}

void sendI2CMaster(uint16_t i2c_addr, uint32_t ledStateOut){

int index = 0;

txData[index++] = (uint8_t) 0x16; /* I2C device regAddr */

txData[index++] = (uint8_t) ((ledStateOut) & 0xff); /* I2C device regVal */

txData[index++] = (uint8_t) ((ledStateOut >> 8) & 0xff);/* I2C device regVal */

txData[index++] = (uint8_t) ((ledStateOut >> 16) & 0xff);/* I2C device regVal */

txData[index++] = (uint8_t) ((ledStateOut >> 24) & 0xff);/* I2C device regVal */

SetupXferRecAndExecute(i2c_addr, txData, 5, rxData, 0);

}

void SysTick_Handler(){

ticks++;

if ((ticks % 50) == 0){event_flag |= EVENT_LED_BUMP;}

if ((ticks % 125) == 0){event_flag |= EVENT_LED_TOGGLE;}

}

int main(){

uint16_t txSize,rxSize,last_Data;

uint8_t i,j,times=16;//LSB,MSB,;

uint32_t sum_data;

SystemCoreClockUpdate();

Board_Init();

Init_I2C_PinMux();

setupI2CMaster();

NVIC_DisableIRQ(I2C_IRQn);

setLcdGPIO();

lcdInit();

lcdClear();

dispBase();

txSize = 2;

rxSize = 0;

txData[0]=0x00;

txData[1]=0x10;// (0x10) [16] 2 [16] 0

SetupXferRecAndExecute(I2C_ADDR_7BIT, txData,txSize, rxData, rxSize);

delay(times);

last_Data=0;

txSize = 1;

rxSize = 2;

while(1){

//Test RGBW a Roller

for(j=0;j<4;j++){

txData[0]=0x08+j;

sum_data=0;

for(i=0;i<times;i++){ //0x10 0x08 1 [16] 2

SetupXferRecAndExecute(I2C_ADDR_7BIT, txData,txSize, rxData, rxSize);

delay(100);

last_Data=((rxData[1]<<8)+rxData[0]);

sum_data+=last_Data;

}

rgb[j]=sum_data/times;

}

js++;

dispMes();

LED_CLR;

delay(times*5);

LED_SET;

}

}

//Display Base

void dispBase(void){

c2l(0,0,42);c2l(0,1,51);//JS

c2l(1,0,33);c2l(1,1,16);c2l(1,8,33);c2l(1,9,17);//A0,A1

c2l(2,0,48);c2l(2,1,55);c2l(2,2,17);c2l(2,8,48);c2l(2,9,55);c2l(2,10,18);//PW0PW1

c2l(3,0,50);c2l(3,1,26);c2l(3,8,39);c2l(3,9,26);//R:G:

c2l(4,0,34);c2l(4,1,26);c2l(4,8,55);c2l(4,9,26);//b:W:

c2l(5,0,48);c2l(5,1,42);c2l(5,2,18);c2l(5,3,24);//PJ28

}

//Display Test

void dispMes(void){

c2l(0,3,16+(js/100000)%10);c2l(0,4,16+(js/10000)%10);c2l(0,5,16+(js/1000)%10);c2l(0,6,16+(js/100)%10);c2l(0,7,16+(js/10)%10);c2l(0,8,16+(js)%10);

c2l(3,3,16+(rgb[0]/1000)%10);c2l(3,4,16+(rgb[0]/100)%10);c2l(3,5,16+(rgb[0]/10)%10);c2l(3,6,16+(rgb[0])%10);

c2l(3,11,16+(rgb[1]/1000)%10);c2l(3,12,16+(rgb[1]/100)%10);c2l(3,13,16+(rgb[1]/10)%10);c2l(3,14,16+(rgb[1])%10);

c2l(4,3,16+(rgb[2]/1000)%10);c2l(4,4,16+(rgb[2]/100)%10);c2l(4,5,16+(rgb[2]/10)%10);c2l(4,6,16+(rgb[2])%10);

c2l(4,10,16+(rgb[3]/10000)%10);c2l(4,11,16+(rgb[3]/1000)%10);c2l(4,12,16+(rgb[3]/100)%10);c2l(4,13,16+(rgb[3]/10)%10);c2l(4,14,16+(rgb[3])%10);

}

改完的程序仅仅完成驱显,1个程序计数器和1只LED闪烁,ADC、PWM、脉冲产生、检测脉冲需要单独在编写。改回标准编码方法,函数的描述非常长,为了准确的描述一个函数,通常需要从某个变量开始搜索整个项目,而后找到对应函数;很多情况是函数套函数,搜到2~3级之后才能找到正确的变量描述和函数的使用。并且,从PIO的定义就可以看出:使用1个GPIO,需要定义口的输出、输出反向、开时钟、定义高或低,等等多个语句才能完成这个口,比起mbed来确是复杂了许多。这绝对不是编写代码的进步,也绝对不是编程人员的福音——倒是加速成为码农——当然,有些工具可以自动生成代码,但长度绝对可以成为想象中的码农采用机械来耕犁那一望无际的码。结果见照片31,32。程序改完后的运行可靠连续半天没有任何情况发生。需要说明的是循环语句中检测RGBW的循环无法摘出成为一个功能函数,结果是检测十分不稳定,少则几个,多则几分钟的采样数据屏幕就不动了。不知道是什么原因。成为独立函数模块后有些变量成为全局变量,有些事私有变量。这点可以大家一起分析找出原因。因为模块化是C的最爱。谢谢。

41-驱显效果示意

42-黄线框表示此LED闪烁