silvaco tcad 沟槽功率MOS求助

时间:03-15

整理:3721RD

点击:

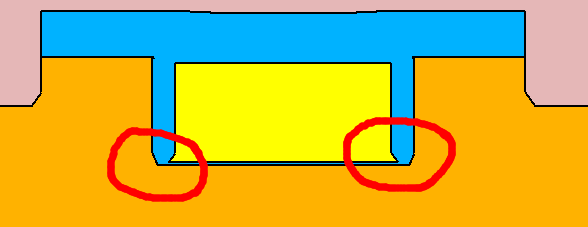

下面是我的工艺过程,我刻蚀沟槽的时候直接用的ETCH而不是etch rate,怎么我的管子出来成了这样

#

line x loc=0.00 spac=0.08

line x loc=0.20 spac=0.05

line x loc=0.40 spac=0.01

line x loc=0.60 spac=0.01

line x loc=0.75 spac=0.01

#

line y loc=0.00 spac=0.01

line y loc=1.00 spac=0.03

line y loc=2.00 spac=0.06

line y loc=3.00 spac=0.08

line y loc=4.00 spac=0.10

line y loc=5.00 spac=0.15

# sub define

init silicon c.arsenic=5e19 orientation=100 two.d

# create sub

etch silicon above p1.y=4

#epi1

deposit silicon thick=1.00 c.arsenic=1.12e15

#epi2

deposit silicon thick=1.00 c.arsenic=1.12e15

#epi3

deposit silicon thick=1.00 c.arsenic=1.12e15

#epi4

deposit silicon thick=1.00 c.arsenic=1.12e15

# trench etch

etch silicon start x=0.50 y=-0.01

etch cont x=0.50 y=1.50

etch cont x=0.75 y=1.50

etch done x=0.75 y=0.00

# annealing

diffus time=2 temp=950 nitro press=1.00

# gate oxidation

diffus time=10 temp=950 dryo2 press=1.00 hcl.pc=3

# gate oxidation

diffus time=10 temp=950 dryo2 press=1.00 hcl.pc=3

# gate oxidation

diffus time=10 temp=950 dryo2 press=1.00 hcl.pc=3

# gate oxidation

diffus time=10 temp=950 dryo2 press=1.00 hcl.pc=3

# gate oxidation

diffus time=10 temp=950 dryo2 press=1.00 hcl.pc=3

# gate oxidation

diffus time=10 temp=950 dryo2 press=1.00 hcl.pc=3

# gate oxide deposit

deposit oxide thick=0.0006 divisions=17

# polysilicon deposit

deposit polysilicon thick=0.93 c.phosphor=1.0e11 divisions=10

# etch polysilicon

etch polysilicon above p1.y=0.1

# etch oxide

etch oxide above p1.y=0.0

# oxide deposit

deposit oxide thick=1.00 divisions=10

# oxide deposit

deposit oxide thick=1.00 divisions=10

# oxide etch

etch oxide left p1.x=0.360

# p-body

implant boron dose=3e13 energy=400 tilt=7 rotation=28 crystal

# oxide etch

etch oxide above p1.y=0.05

# oxide deposit

deposit oxide thick=1.00 divisions=10

# oxide etch

etch oxide start x=0.23 y=-1.00

etch cont x=0.23 y=0.03

etch cont x=0.43 y=0.03

etch done x=0.43 y=-1.00

# n+

implant arsenic dose=1.2e14 energy=350 tilt=7 rotation=28 crystal

# annealing

diffus time=3 temp=950 nitro press=1.00

# oxide etch

etch oxide above p1.y=0.05

# pbody etch

etch silicon start x=0.00 y=0.00

etch cont x=0.00 y=0.70

etch cont x=0.25 y=0.70

etch done x=0.25 y=-0.01

# oxide deposit

deposit oxide thick=1.00 divisions=10

# 0xide etch

etch oxide left p1.x=0.23

# p+

implant boron dose=1e14 energy=100 tilt=7 rotation=28 crystal

# annealing

diffus time=3 temp=950 nitro press=1.00

# 0xide etch

etch oxide above p1.y=0.05

# oxide etch

etch oxide left p1.x=0.25

# bpsg deposit

deposit oxide thick=0.65 c.arsenic=1.0e11 c.boron=1.0e11 divisions=10

# bpsg etch

etch oxide left p1.x=0.25

# aluminum deposit

deposit aluminum thick=0.35 divisions=10

#

struct mirror right

#

electrode name=source x=0.40 y=0.15

#

electrode name=source x=1.10 y=0.15

#

electrode name=gate x=0.75 y=0.90

#

electrode name=drAIn backside

#

line x loc=0.00 spac=0.08

line x loc=0.20 spac=0.05

line x loc=0.40 spac=0.01

line x loc=0.60 spac=0.01

line x loc=0.75 spac=0.01

#

line y loc=0.00 spac=0.01

line y loc=1.00 spac=0.03

line y loc=2.00 spac=0.06

line y loc=3.00 spac=0.08

line y loc=4.00 spac=0.10

line y loc=5.00 spac=0.15

# sub define

init silicon c.arsenic=5e19 orientation=100 two.d

# create sub

etch silicon above p1.y=4

#epi1

deposit silicon thick=1.00 c.arsenic=1.12e15

#epi2

deposit silicon thick=1.00 c.arsenic=1.12e15

#epi3

deposit silicon thick=1.00 c.arsenic=1.12e15

#epi4

deposit silicon thick=1.00 c.arsenic=1.12e15

# trench etch

etch silicon start x=0.50 y=-0.01

etch cont x=0.50 y=1.50

etch cont x=0.75 y=1.50

etch done x=0.75 y=0.00

# annealing

diffus time=2 temp=950 nitro press=1.00

# gate oxidation

diffus time=10 temp=950 dryo2 press=1.00 hcl.pc=3

# gate oxidation

diffus time=10 temp=950 dryo2 press=1.00 hcl.pc=3

# gate oxidation

diffus time=10 temp=950 dryo2 press=1.00 hcl.pc=3

# gate oxidation

diffus time=10 temp=950 dryo2 press=1.00 hcl.pc=3

# gate oxidation

diffus time=10 temp=950 dryo2 press=1.00 hcl.pc=3

# gate oxidation

diffus time=10 temp=950 dryo2 press=1.00 hcl.pc=3

# gate oxide deposit

deposit oxide thick=0.0006 divisions=17

# polysilicon deposit

deposit polysilicon thick=0.93 c.phosphor=1.0e11 divisions=10

# etch polysilicon

etch polysilicon above p1.y=0.1

# etch oxide

etch oxide above p1.y=0.0

# oxide deposit

deposit oxide thick=1.00 divisions=10

# oxide deposit

deposit oxide thick=1.00 divisions=10

# oxide etch

etch oxide left p1.x=0.360

# p-body

implant boron dose=3e13 energy=400 tilt=7 rotation=28 crystal

# oxide etch

etch oxide above p1.y=0.05

# oxide deposit

deposit oxide thick=1.00 divisions=10

# oxide etch

etch oxide start x=0.23 y=-1.00

etch cont x=0.23 y=0.03

etch cont x=0.43 y=0.03

etch done x=0.43 y=-1.00

# n+

implant arsenic dose=1.2e14 energy=350 tilt=7 rotation=28 crystal

# annealing

diffus time=3 temp=950 nitro press=1.00

# oxide etch

etch oxide above p1.y=0.05

# pbody etch

etch silicon start x=0.00 y=0.00

etch cont x=0.00 y=0.70

etch cont x=0.25 y=0.70

etch done x=0.25 y=-0.01

# oxide deposit

deposit oxide thick=1.00 divisions=10

# 0xide etch

etch oxide left p1.x=0.23

# p+

implant boron dose=1e14 energy=100 tilt=7 rotation=28 crystal

# annealing

diffus time=3 temp=950 nitro press=1.00

# 0xide etch

etch oxide above p1.y=0.05

# oxide etch

etch oxide left p1.x=0.25

# bpsg deposit

deposit oxide thick=0.65 c.arsenic=1.0e11 c.boron=1.0e11 divisions=10

# bpsg etch

etch oxide left p1.x=0.25

# aluminum deposit

deposit aluminum thick=0.35 divisions=10

#

struct mirror right

#

electrode name=source x=0.40 y=0.15

#

electrode name=source x=1.10 y=0.15

#

electrode name=gate x=0.75 y=0.90

#

electrode name=drAIn backside

some one upload tutorial

http://bbs.eetop.cn/thread-380063-1-1.html