第三篇?Rico Board使用 hrt高精度时钟驱动舵机

时间:10-02

整理:3721RD

点击:

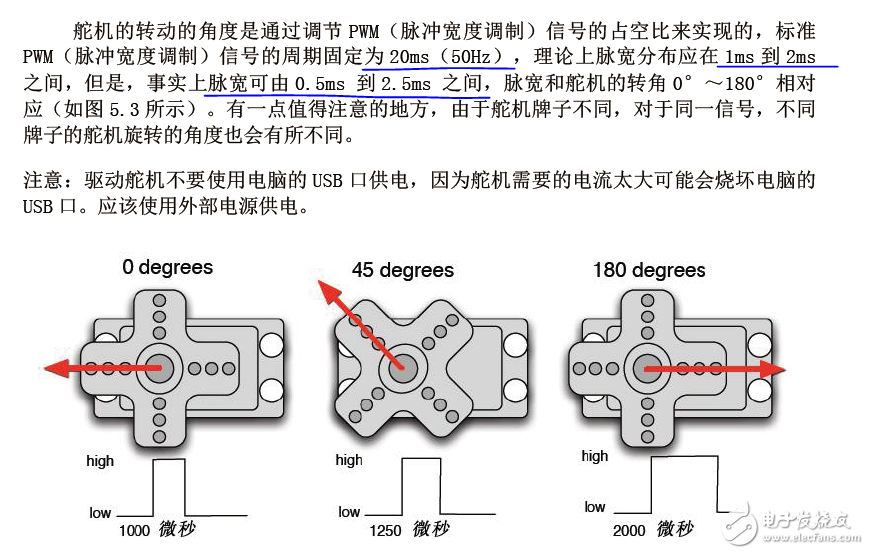

首先科普一下舵机驱动的要求:

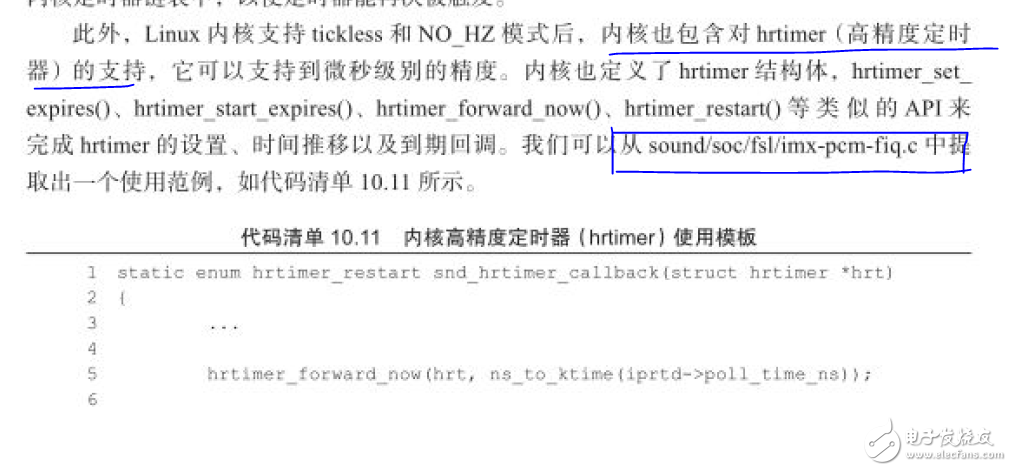

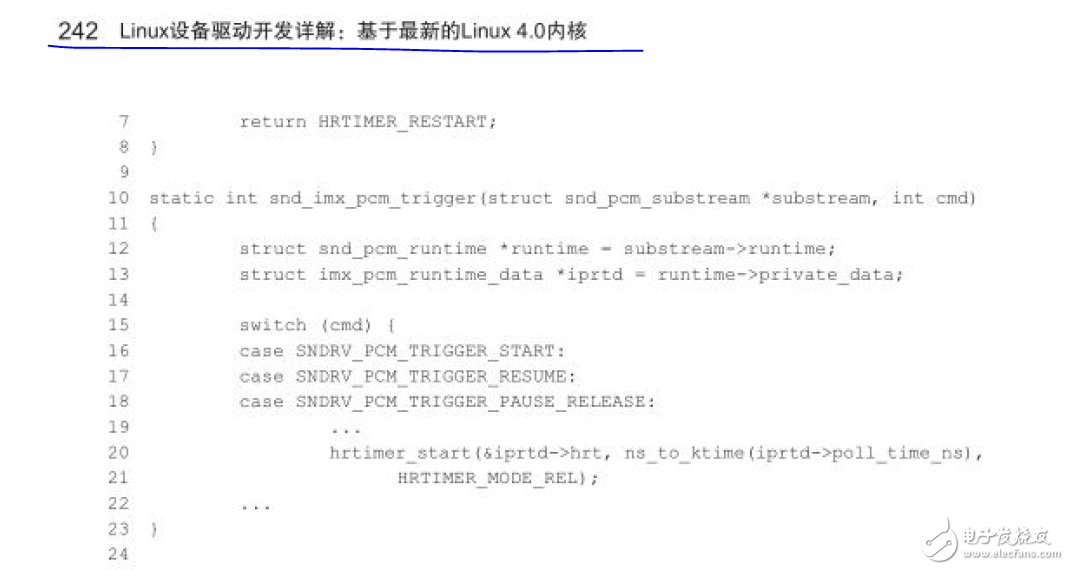

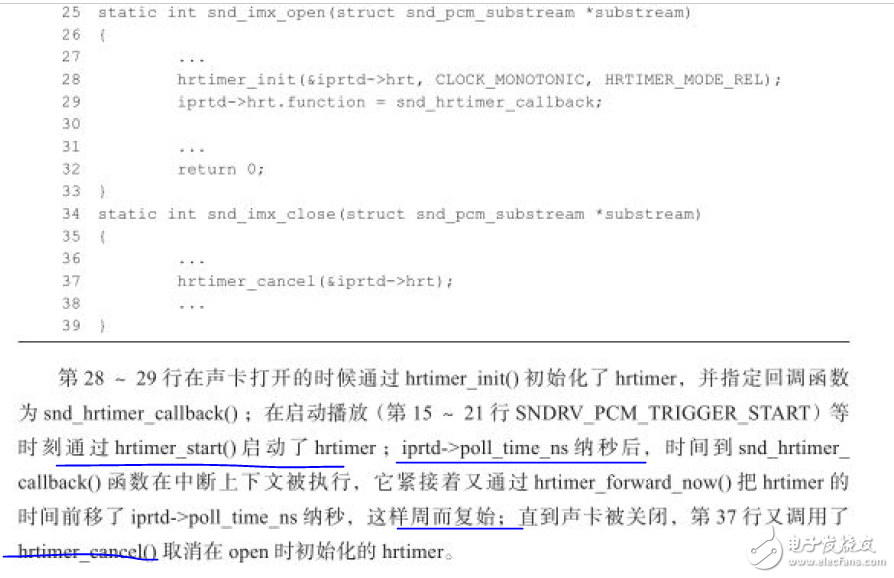

既然周期是20ms,脉宽处在0.5ms~2.5ms。所以,普通的内核定时器就不能满足要求了,就要用到高精度定时器。我主要参考的内容如下:

这都是摘自宋宝华的《Linux设备驱动开发详解基于最新的Linux4.0内核》。

我的代码如下:

- /**

- * [url=home.php?mod=space&uid=1455510]@file[/url] motor.c

- * [url=home.php?mod=space&uid=40524]@author[/url] yang yongsheng

- * @date 2016.11.2

- */

- #include

- #include

- #include

- #include // Required for the GPIO functions

- #include

- #include

- #include

- #include

- #include

- #include

- #include

- #include

- #include

- #define NAME_LEN 16

- /*gpio5_8*/

- //#define MOTOR_GPIO_NUM 168

- /*gpio5_9*/

- #define LED_GPIO_NUM 169

- #define MOTOR_NUM 1

- #define MOTOR_NAME "rico_lan motor"

- #define MOTOR_MAJOR 0

- static int motor_major = MOTOR_MAJOR;

- static dev_t motor_dev_num;

- int motor_gpio[MOTOR_NUM] = {113};

- MODULE_LICENSE("GPL");

- MODULE_AUTHOR("yang yongsheng ");

- MODULE_VERSION("0.1");

- struct motor_dev{

- struct cdev cdev;

- int num;

- unsigned int pwm_value_us;

- struct hrtimer hrt;

- char name[NAME_LEN];

- bool pwm_state;

- } *motor_devp;

- struct class *motor_class;

- static enum hrtimer_restart motor_hrtimer_callback(struct hrtimer *hrt)

- {

- struct motor_dev *devp_tmp;

- devp_tmp = container_of(hrt, struct motor_dev, hrt);

- devp_tmp->pwm_state = !devp_tmp->pwm_state;

- gpio_set_value(devp_tmp->num, devp_tmp->pwm_state);

- if(devp_tmp->pwm_state == false)

- hrtimer_forward_now(hrt, ns_to_ktime((20000-devp_tmp->pwm_value_us)*1000));//T=20,000ns

- else if(devp_tmp->pwm_state == true)

- hrtimer_forward_now(hrt, ns_to_ktime((devp_tmp->pwm_value_us) * 1000));//T=20,000ns

- //printk(KERN_INFO "hrt time is %d",devp_tmp->pwm_value_us);

- return HRTIMER_RESTART;

- }

- int motor_open (struct inode *inode, struct file *filp)

- {

- struct motor_dev *devp_tmp;

- devp_tmp = container_of(inode->i_cdev, struct motor_dev, cdev);

- filp->private_data = devp_tmp;

- hrtimer_init(&devp_tmp->hrt, CLOCK_MONOTONIC, HRTIMER_MODE_REL);

- devp_tmp->hrt.function = motor_hrtimer_callback;

- gpio_set_value(devp_tmp->num, devp_tmp->pwm_state);

- hrtimer_start(&devp_tmp->hrt, ns_to_ktime(devp_tmp->pwm_value_us), HRTIMER_MODE_REL);

- printk(KERN_INFO "motor_open.\n");

- return 0;

- }

- int motor_release (struct inode *inode, struct file *filp)

- {

- struct motor_dev *devp_tmp;

- devp_tmp = filp->private_data;

- printk(KERN_INFO "motor_release and pwm_value_us is %d.\n", devp_tmp->pwm_value_us);

- return 0;

- }

- ssize_t motor_write (struct file *filp, const char __user *buf, size_t count, loff_t *ppos)

- {

- char pwm_value_tmp[8];

- struct motor_dev *motor_devp_tmp = filp->private_data;

- copy_from_user(pwm_value_tmp, buf, sizeof(buf));

- gpio_set_value(LED_GPIO_NUM , motor_devp_tmp->pwm_state);

- motor_devp_tmp->pwm_value_us = simple_strtoul(pwm_value_tmp, NULL, 10);

- if(motor_devp_tmp->pwm_value_us > 2500)

- motor_devp_tmp->pwm_value_us = 2500;

- else if(motor_devp_tmp->pwm_value_us pwm_value_us = 500;

- printk(KERN_INFO "pwm_value is %d.\n", motor_devp_tmp->pwm_value_us);

- printk(KERN_INFO "motor_write.\n");

- return count;

- }

- static struct file_operations motor_fops =

- {

- .owner = THIS_MODULE,

- .open = motor_open,

- .release = motor_release,

- .write = motor_write,

- };

- int motor_setup(struct motor_dev *devp, int min, int num)

- {

- int ret = 0;

- sprintf(devp->name, "motor%d", min);

- if(!gpio_is_valid(num))

- {

- printk(KERN_INFO "invalid motor%d_gpio_num:%d.\n",min, num);

- return -ENODEV;

- }

- else

- {

- gpio_request(num, "sysfs");

- gpio_direction_output(num, false);

- gpio_export(num, false); /*cause GPIO_NUM to appear in /sys/class/gpio*/

- }

- devp->num = num;

- devp->pwm_value_us = 1500;//500~2500 us

- devp->pwm_state = true;

- devp->cdev.owner = THIS_MODULE;

- cdev_init(&devp->cdev, &motor_fops);

- ret = cdev_add(&devp->cdev, MKDEV(motor_major, min), 1);

- if(ret)

- {

- printk(KERN_INFO "error %d adding motor%d.\n", ret, min);

- }

- else

- {

- device_create(motor_class, NULL, MKDEV(motor_major, min), NULL,devp->name);

- }

- return 0;

- }

- int __init motor_init(void)

- {

- int ret,i;

- printk(KERN_INFO "motor_init begin.\n");

- if(!gpio_is_valid(LED_GPIO_NUM))

- {

- printk(KERN_INFO "invalid LED_GPIO_NUM:%d.\n",LED_GPIO_NUM);

- return -ENODEV;

- }

- motor_devp = kzalloc(sizeof(struct motor_dev) * MOTOR_NUM, GFP_KERNEL);

- if(IS_ERR(motor_devp))

- {

- printk(KERN_INFO "no space for motor_dev.\n");

- return -ENOMEM;

- }

- motor_class = class_create(THIS_MODULE, MOTOR_NAME);

- if(motor_major == 0)

- {

- ret = alloc_chrdev_region(&motor_dev_num, 0, MOTOR_NUM, MOTOR_NAME);

- motor_major = MAJOR(motor_dev_num);

- }

- else

- {

- motor_dev_num = MKDEV(motor_major, 0);

- ret = register_chrdev_region(motor_dev_num, MOTOR_NUM, MOTOR_NAME);

- }

- if(ret hrt);

- gpio_unexport((motor_devp+i)->num);

- gpio_free((motor_devp+i)->num);

- device_destroy(motor_class,MKDEV(motor_major,i));

- cdev_del(&(motor_devp+i)->cdev);

- unregister_chrdev_region(MKDEV(motor_major, i), 1);

- kfree(motor_devp+i);

- }

- gpio_unexport(LED_GPIO_NUM);

- gpio_free(LED_GPIO_NUM);

- class_destroy(motor_class);

-

- printk(KERN_INFO "motor_exit finished.\n");

- }

- module_init(motor_init);

- module_exit(motor_exit);

实现的内容:

往字符设备/dev/motor0 写入脉宽的时间(500ns~2500ns)可以自动修正超界的脉宽值。可以控制舵机旋转角度在(0~180)。

驱动舵机的GPIO为GPIO3_17 (也就是113号引脚,程序里面有体现)。

现场视频(用户程序控制输出脉宽每1s,增加50us),已经上传到了优酷:

1。示波器显示,

http://v.youku.com/v_show/id_XMTc4NTUyMTM4NA==.html

2。现场舵机转动:

http://v.youku.com/v_show/id_XMTc4NTUyMjIzNg==.html

下面记录下我的整个实验过程:

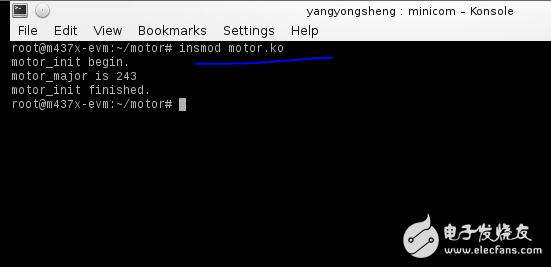

1.安装编译好的模块,自动创建设备节点/dev/motor0

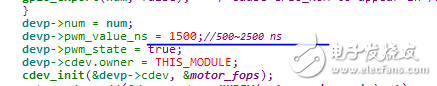

2.查看默认输出的脉宽1500ns:

关键代码如下:

查看波形,脉宽1.52ms:

周期20ms:

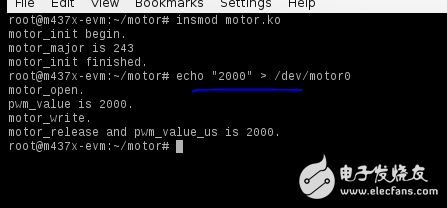

3.命令行下,手动更改脉宽到2000ns:

脉宽显示2ms

4.放上几张现场图片,挺乱的,太懒了我,东西都堆在一起了。

这次主要学到了两点:

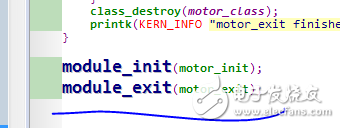

(1)module_init和module_exit用大写时就出错了,要记得用小写。

(2)知道了高精度定时器hrt的使用方法。

这个 ,大材小用了吧,即使RicoBoard能输出超精密的PWM波,舵机也不见得能分辨的过来啊

那还能有什么好办法实现啊?